Polema plant mastered production of new powders for import substitution

In this article, we are talking not of desktop 3D printers like the Creatbot DE but about powders for the production of metal parts.

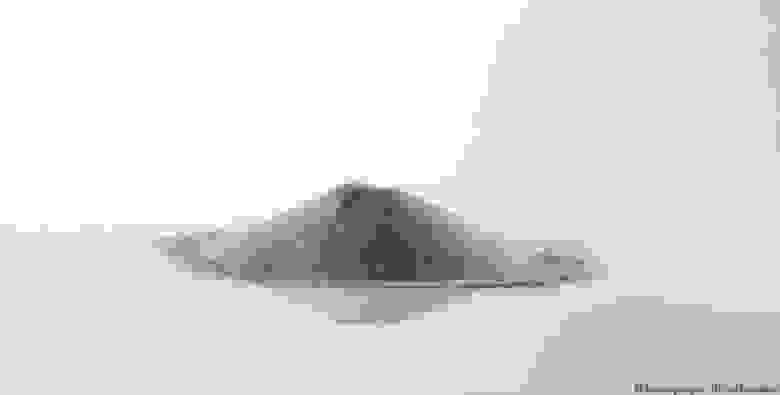

The Tula powder metallurgy plant Polema (part of the Industrial and Metallurgical Holding) has mastered the production of high-entropy alloys and NiCrAlY coatings for import substitution in aircraft construction and other industries. These alloys are suitable for the manufacture of products using 3D printing.

The enterprise started the production of high-entropy alloys PR-KKh23N26, PR-NKh24K24Yu, PR-NKh23K23Yu, PR-NKh18K18D20Yu, PR-NKh21K21G20, and PR-NKh20K20D21 by means of gas atomization.

The advantages of the new materials include high corrosion resistance, the ability to maintain strength and flexibility at ultra-low temperatures, and a stable phase composition during thermomechanical processing.

Polema also mastered the production of two grades of NiCrAlY alloys used as a metal sublayer for heat-shielding coatings on parts of internal combustion engines: PR-NH22Yu10It (Amdry 962 analog) and PR-KhN67Yu12 (similar to Amperit 457.642, additionally doped with hafnium and rhenium) with the help of gas atomization, too. Previously, the production of alloys of the NiCrAlY system at JSC Polema was carried out by the method of joint reduction of oxides with calcium hydride.

«Polema continues to master new types of products which have no analogues in Russia. This is our contribution to the import substitution program. The new products will be used in aircraft construction, medicine, and a number of other industries,» commented managing director Alexey Filippov.

Habrahabr.ru прочитано 5736 раз